|

Specifications:

|

|

炉体结构

|

Double layer steel case with mullite liner without water cooling or air cooling

|

|

加热元件

|

8 根碘钨灯管 (D=10 L=300 T =200, mm)

|

|

加热区

|

加热区12" 、恒温区 4"、恒温精度±5℃

|

|

炉管 &样品支架

|

|

|

密封系统

|

-

密封系统由不锈钢法兰、精密针阀及硅胶O型圈构成.

-

滑轨式法兰,放取样品更加方便

|

|

水冷机构

|

|

|

Flow-meter

|

One flow meter is installed on the front panel to adjust gas flow from 0 - 160 ml/min

|

|

Vacuum gauge

|

Digital vacuum gauge with a measurement range from 1 mtorr~800 torr is installed with the furnace.

|

|

Vacuum pressure & Gas Fitting

|

-

In order to increase the throughput and achieve high vacuum, you may replace the standard barbed hose fitting with the KF25 adapter, please click underline to order.

-

For supplying high pressure gas, you may replace the standard barbed hose fitting with the VCR Face Seal Fitting, please click underline to order.

|

|

Temperature control

|

PID automatic control via SCR (Silicon Controlled Rectifier) power control, e.g. current limiting phase angle fired the resistor.

|

|

Thermal Couple

|

S type, the head of the thermocouple touches the Aluminum Nitride sample holder from underneath

|

|

Programmable Temperature controller

|

|

|

Max. Heating Rate

|

50ºC/sec recommended, and 120ºC/sec. for short time

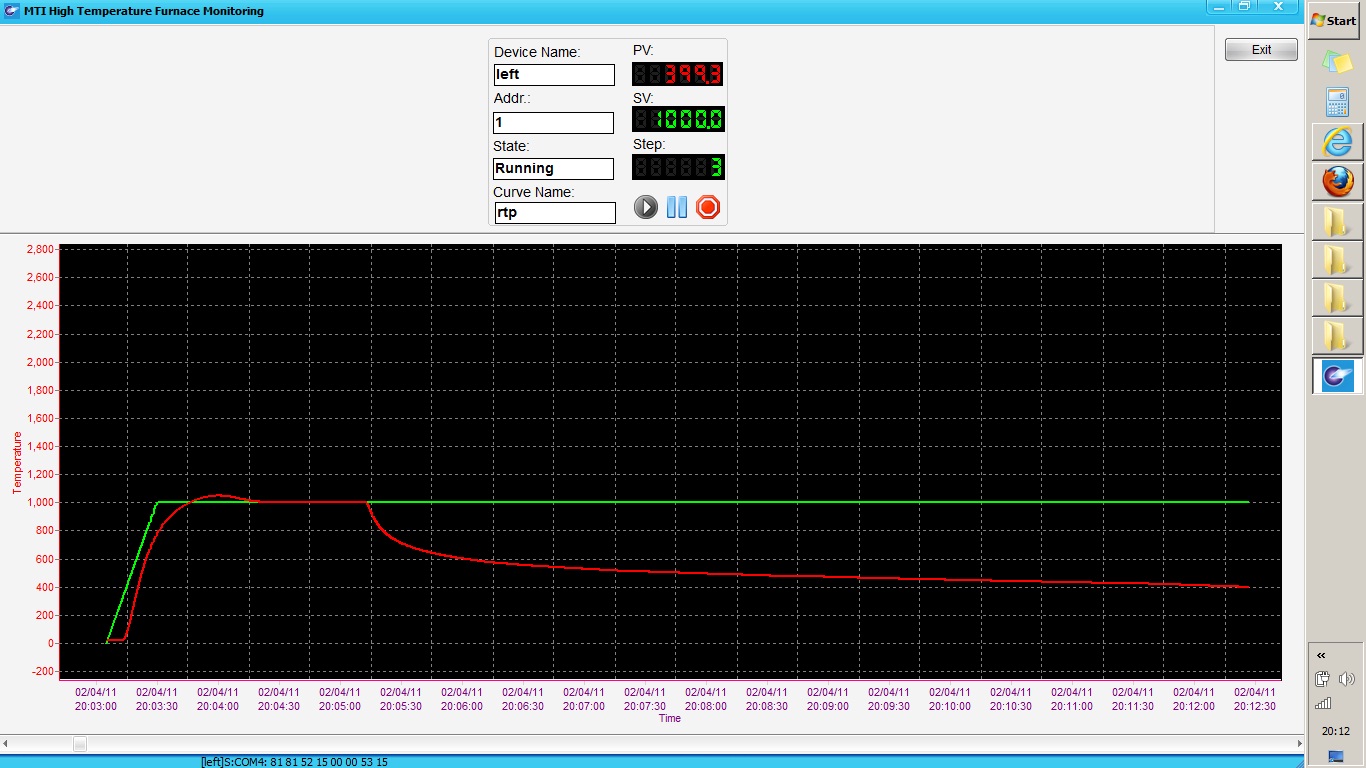

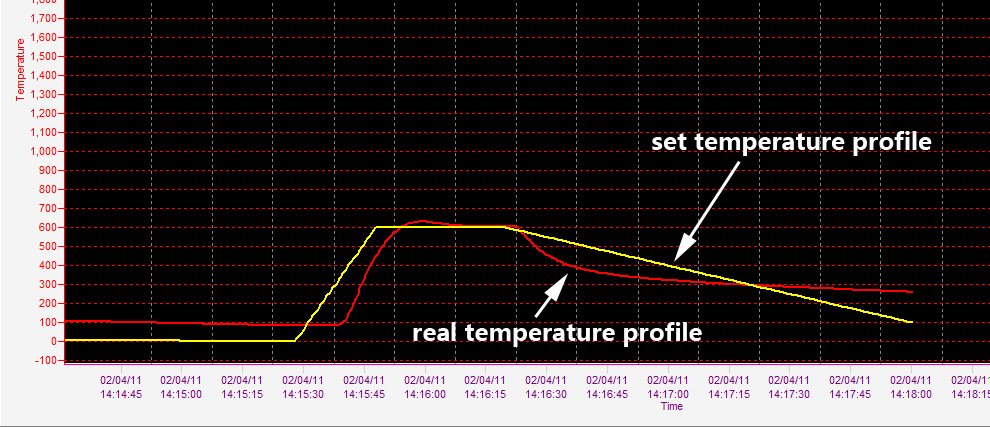

1000ºC heating profile

|

800°C heating profile

|

700°C heating profile

|

600°C heating profile

|

|

|

Max. Cooling Rate

|

64ºC/min (Under vacuum: 200 mtorr), 117ºC/min (Under atmosphere pressure)

|

|

Working Temperature

|

1100ºC Max.

|

|

Power Input

|

208-240 AC, 50/60 Hz single phase, 9 KW Max. (> 60A breaker required)

|

|

Dimension

|

760 X 330 X 530 mm (30"W x 13"L x 21" H)

|

|

Net weight

|

45 kg (100 lbs)

|

|

Warranty

|

One year limited warranty for electrical parts. (Consumable parts such as processing tubes, o-rings and halogen lamp are not covered by the warranty, please order the replacement at related products below.)

|

|

Certificate

|

CE certified CE certified

|